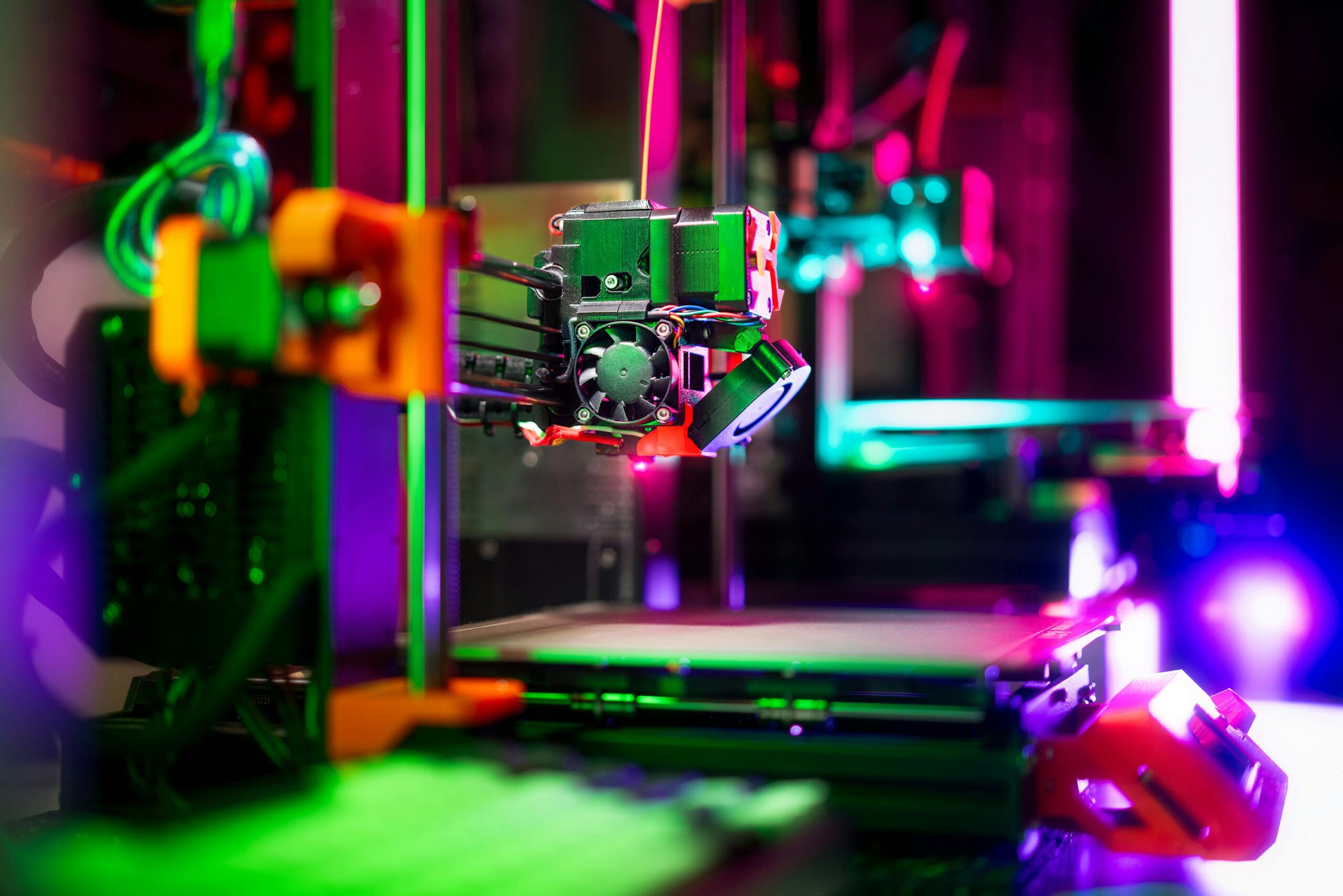

The intersection of 3D printing technology and environmental sustainability is reshaping manufacturing as we know it. This revolutionary approach combines cutting-edge additive manufacturing with eco-conscious materials, creating opportunities for a greener industrial future.

As climate concerns intensify globally, industries are reimagining production methods to minimize environmental impact. 3D printing, once primarily focused on rapid prototyping and innovation, now stands at the forefront of sustainable manufacturing. By incorporating recycled plastics, biodegradable polymers, and natural materials, this technology is proving that industrial advancement and environmental responsibility can coexist harmoniously.

🌱 The Environmental Challenge in Traditional Manufacturing

Traditional manufacturing processes have long contributed significantly to environmental degradation. Conventional production methods typically involve subtractive manufacturing, where materials are cut, drilled, or shaped from larger blocks, resulting in substantial waste. Studies indicate that traditional manufacturing can waste up to 30-40% of raw materials, which often end up in landfills.

The carbon footprint of conventional manufacturing extends beyond material waste. Energy-intensive processes, long supply chains, and transportation of finished goods across continents contribute to greenhouse gas emissions. The packaging required for shipping adds another layer of environmental burden, with single-use plastics dominating the landscape.

These challenges have created an urgent need for alternative production methods. The manufacturing sector accounts for approximately 20% of global CO2 emissions, making it imperative to explore innovative solutions that reduce both waste and energy consumption while maintaining production efficiency.

Additive Manufacturing: A Paradigm Shift in Production

3D printing represents a fundamental departure from traditional manufacturing philosophy. Unlike subtractive methods, additive manufacturing builds objects layer by layer, using only the material necessary for the final product. This precision-driven approach dramatically reduces waste, with some estimates suggesting waste reduction of up to 90% compared to conventional methods.

The technology enables on-demand production, eliminating the need for large inventories and reducing storage requirements. Manufacturers can produce items locally, near the point of consumption, significantly cutting transportation emissions. This decentralized production model transforms supply chains, making them more resilient and environmentally friendly.

Beyond waste reduction, 3D printing allows for complex geometries and optimized designs that use less material while maintaining structural integrity. Engineers can create lightweight components with internal lattice structures that would be impossible to manufacture using traditional methods, further enhancing material efficiency.

The Speed of Transformation

The adoption rate of sustainable 3D printing has accelerated dramatically in recent years. Industries ranging from automotive to fashion are integrating this technology into their production lines. Major corporations are investing billions in additive manufacturing facilities that prioritize eco-friendly materials, signaling a significant shift in industrial priorities.

♻️ Recycled Materials Leading the Green Revolution

The integration of recycled materials into 3D printing represents one of the most promising developments in sustainable manufacturing. Recycled plastics, particularly PET from bottles and HDPE from containers, are being transformed into high-quality printing filaments. This circular economy approach diverts waste from landfills while creating valuable manufacturing inputs.

Companies worldwide are developing systems to collect, process, and convert plastic waste into printable materials. These recycled filaments maintain comparable strength and durability to virgin materials, making them viable for functional parts rather than just prototypes. The quality improvements in recycled materials have been remarkable, with some recycled filaments now outperforming their non-recycled counterparts in specific applications.

Ocean plastics have become a particular focus for sustainability-minded manufacturers. Organizations are harvesting plastic waste from oceans and waterways, processing it into filament that tells a powerful environmental story. Products made from ocean-recovered plastics carry both functional and symbolic value, demonstrating tangible environmental impact.

Beyond Plastic: Diverse Recycled Materials

Innovation extends beyond traditional plastics. Metal 3D printing now incorporates recycled aluminum, steel, and titanium powders, offering sustainable alternatives in aerospace and industrial applications. Wood composites mixed with recycled binding agents create unique materials with natural aesthetics and reduced environmental footprints.

Even electronic waste is finding new life in 3D printing applications. Researchers are developing methods to extract and reprocess materials from discarded electronics, creating conductive filaments for specialized applications. This approach addresses the growing e-waste crisis while creating valuable manufacturing materials.

Biodegradable and Bio-Based Materials: Nature’s Answer

While recycled materials address existing waste, biodegradable materials prevent future pollution. PLA (polylactic acid), derived from renewable resources like corn starch and sugarcane, has become the most popular bio-based 3D printing material. Unlike petroleum-based plastics, PLA decomposes under industrial composting conditions, returning to the earth without leaving harmful residues.

Advanced bio-materials are pushing boundaries further. Hemp-based filaments combine rapid renewability with impressive strength characteristics. Algae-derived materials offer carbon-negative production processes, actually removing CO2 from the atmosphere during growth. Mycelium composites, grown from mushroom roots, create entirely compostable materials with unique properties.

The performance of these bio-materials continues to improve through research and development. Scientists are enhancing their heat resistance, durability, and mechanical properties, expanding their applicability beyond prototypes into functional end-use parts. Some bio-based materials now rival traditional plastics in strength while maintaining their environmental advantages.

Agricultural Waste Transformation

Agricultural byproducts are emerging as valuable 3D printing materials. Rice husks, coffee grounds, and wood sawdust are being incorporated into composite filaments, giving agricultural waste new purpose. These materials reduce dependence on virgin resources while supporting circular economies in agricultural communities.

🏭 Industrial Applications Driving Sustainable Change

The automotive industry has embraced sustainable 3D printing enthusiastically. Major manufacturers are producing spare parts, interior components, and even structural elements using recycled and bio-based materials. This approach reduces vehicle weight, improving fuel efficiency while minimizing manufacturing waste.

Aerospace companies are leveraging 3D printing’s ability to create lightweight, complex geometries from sustainable materials. Every kilogram saved in aircraft weight translates to significant fuel savings over the vehicle’s lifetime, multiplying the environmental benefits. Recycled titanium and aluminum alloys are becoming standard in next-generation aircraft components.

The construction industry is witnessing revolutionary changes through large-scale 3D printing with sustainable materials. Entire building components, including walls and structural elements, are being printed using concrete mixtures that incorporate recycled aggregates and industrial byproducts. This approach reduces construction waste, speeds up building processes, and lowers costs.

Fashion and Consumer Goods

Fashion designers are creating innovative products using 3D-printed textiles from recycled materials. Shoes, accessories, and even clothing items showcase how sustainable manufacturing can meet aesthetic and functional requirements. These products demonstrate that environmental responsibility doesn’t require compromising on design or quality.

Consumer electronics manufacturers are incorporating 3D-printed components from recycled materials into devices, reducing their environmental footprint. Phone cases, laptop components, and accessory items made from ocean plastics or bio-based materials appeal to environmentally conscious consumers while performing reliably.

The Economic Viability of Sustainable 3D Printing

Cost considerations have historically challenged sustainable manufacturing adoption, but 3D printing is changing this calculation. The reduced material waste inherent to additive manufacturing lowers raw material costs significantly. When using recycled materials, costs decrease further, as recycled feedstocks are often less expensive than virgin materials.

Local production capabilities reduce transportation expenses and enable faster market response. Companies can manufacture products near consumers, eliminating international shipping costs and reducing inventory requirements. This distributed manufacturing model enhances business resilience while improving sustainability metrics.

Energy consumption patterns favor sustainable 3D printing as well. While individual prints may be energy-intensive, the elimination of multiple production steps, reduced transportation, and decreased waste processing create net energy savings across the product lifecycle. As renewable energy becomes more prevalent, these advantages will amplify.

Investment and Market Growth

Venture capital and corporate investment in sustainable 3D printing technologies has surged. Market analysts project the eco-friendly 3D printing materials sector to grow at compound annual rates exceeding 20% through the next decade. This growth trajectory indicates strong commercial confidence in sustainable additive manufacturing’s viability.

🔬 Technological Innovations Advancing Sustainability

Material science breakthroughs continue expanding sustainable 3D printing possibilities. Researchers are developing composite materials that combine recycled plastics with natural fibers, creating materials stronger than their individual components. These innovations enable applications previously reserved for traditional high-performance materials.

Advanced recycling technologies are improving the quality of recycled printing materials. Chemical recycling processes break plastics down to molecular levels, removing contaminants and degradation that limited mechanical recycling effectiveness. These processes create recycled materials virtually indistinguishable from virgin materials in performance.

Software developments optimize designs for sustainability. Generative design algorithms create components using minimal material while maximizing strength. Topology optimization ensures every gram of material serves a structural purpose, eliminating waste without compromising functionality.

Multi-Material and Color Mixing Technologies

New printer technologies enable simultaneous use of multiple sustainable materials, creating products with varied properties in single prints. This capability reduces assembly requirements and material diversity, simplifying recycling at end-of-life. Full-color printing with natural pigments eliminates toxic dyes, further enhancing environmental profiles.

Challenges and Opportunities Ahead

Despite tremendous progress, sustainable 3D printing faces challenges requiring ongoing attention. Material consistency in recycled feedstocks can vary, affecting print quality and reliability. Developing robust quality control processes for recycled materials remains a priority for commercial-scale adoption.

Print speed limitations compared to mass production methods still constrain some applications. While perfect for customized, low-volume production, 3D printing struggles to compete with injection molding for high-volume identical items. However, technological advances continue narrowing this gap, with newer printers achieving increasingly competitive speeds.

Biodegradable materials sometimes lack the durability required for long-life applications. While perfect for temporary items, short-lifecycle products, or disposable components, bio-materials need further development for applications requiring decades of service. Research focuses on creating biodegradable materials that remain stable during use but decompose rapidly when discarded properly.

Regulatory and Certification Frameworks

Establishing standardized certifications for sustainable 3D printing materials would accelerate adoption. Clear guidelines on what qualifies as eco-friendly, recycled content percentages, and biodegradability standards would help manufacturers and consumers make informed choices. Industry organizations are working toward these standards, though comprehensive frameworks remain under development.

🌍 Global Impact and Future Vision

The potential global impact of widespread sustainable 3D printing adoption is profound. If even 25% of traditional manufacturing shifted to sustainable additive methods, millions of tons of waste could be diverted from landfills annually. Carbon emissions could decrease substantially through localized production and reduced transportation requirements.

Developing nations stand to benefit significantly from accessible 3D printing technology. Local production capabilities using recycled materials can reduce dependence on imported goods, strengthen local economies, and address waste management challenges simultaneously. This technology democratizes manufacturing, enabling communities to create solutions tailored to their specific needs.

Educational initiatives introducing sustainable 3D printing to students cultivate environmental awareness while teaching valuable technical skills. Young people learning to transform waste into useful products develop circular economy mindsets that will shape future industrial practices. This educational foundation is crucial for long-term sustainable manufacturing transformation.

Collaborative Ecosystems

Success requires collaboration across industries, governments, and communities. Material suppliers, printer manufacturers, software developers, and end-users must work together to optimize sustainable practices. Open-source initiatives sharing designs and techniques accelerate innovation by allowing global communities to build upon each other’s work.

Empowering Individual Action and Community Innovation

Sustainable 3D printing isn’t limited to large corporations. Desktop printers using eco-friendly materials are increasingly affordable, enabling individuals to participate in sustainable manufacturing. Makerspaces and community workshops provide access to equipment, fostering local innovation and environmental consciousness.

Enthusiasts are developing creative applications for recycled materials, from household items to artistic creations. Online communities share designs, techniques, and material recipes, creating a global knowledge base. This grassroots movement complements industrial efforts, demonstrating sustainability’s viability at every scale.

Small businesses leveraging sustainable 3D printing create differentiated products appealing to environmentally conscious consumers. Customization capabilities allow these businesses to compete with mass manufacturers by offering personalized, sustainable alternatives. This entrepreneurial ecosystem drives innovation while promoting environmental values.

The Path Forward: Integration and Innovation

The future of sustainable 3D printing lies in deeper integration with circular economy principles. Closed-loop systems where products are designed for eventual recycling back into printing materials will become standard. Design-for-disassembly approaches will facilitate material recovery, ensuring resources remain in productive use indefinitely.

Artificial intelligence and machine learning will optimize material usage and print parameters, maximizing efficiency and minimizing waste. Predictive algorithms will match materials to applications perfectly, ensuring optimal performance while maintaining sustainability. These intelligent systems will make sustainable choices the easiest and most economical options.

The convergence of sustainable 3D printing with other green technologies creates synergistic benefits. Solar-powered printing facilities, carbon capture systems integrated into material production, and water-based printing processes represent the next frontier. This holistic approach addresses environmental concerns comprehensively rather than in isolation.

As technology advances and awareness grows, sustainable 3D printing will transition from innovative exception to industry standard. The question will shift from whether to adopt sustainable practices to how quickly organizations can implement them. This transformation represents not just technological evolution but a fundamental reimagining of humanity’s relationship with manufacturing and materials.

The revolution in 3D printing through sustainable innovation demonstrates that environmental responsibility and technological progress are not opposing forces but complementary objectives. By crafting a greener future with recycled and eco-friendly materials, we’re not limiting possibilities—we’re expanding them. This approach proves that the most innovative solutions often align with nature’s wisdom, creating systems that sustain rather than deplete, build rather than waste, and inspire rather than compromise. The future of manufacturing is being printed today, one sustainable layer at a time, constructing not just products but a legacy of environmental stewardship for generations to come.

Toni Santos is a financial storyteller and blockchain researcher exploring how digital economies transform trust, governance, and creativity. Through his work, Toni studies the evolution of money — from tangible systems to algorithmic value — and how technology reshapes the ethics of exchange. Fascinated by decentralized networks and the philosophy of finance, he analyzes how human decisions interact with algorithms, regulation, and cultural behavior in digital markets. Combining economic theory, data analysis, and narrative insight, Toni translates the complexity of blockchain and decentralized finance into accessible reflections on innovation and responsibility. His work is a tribute to: The pursuit of transparency in financial innovation The creative potential of blockchain ecosystems The shared responsibility of shaping ethical digital economies Whether you are passionate about crypto assets, decentralized finance, or the future of regulation, Toni invites you to explore the intersections of trust, technology, and transformation.